Technical details

Requirements and quality standards of folding boxes may be different, depending on their purpose, however, are increasing constantly.

For applications such as pharmaceuticals, expensive cosmetics , certain foods, cigarettes or any other high-value products these demands are extremely high.

CHECKmaster – offline inspecting and sorting machine – meets all these requirements .

The solution incorporates VisionExpert 4000 CARTON software which has been integrated with VARIOmatic machine.

CHECKmaster can detect various faults in pre-defined areas or whole blanks and simultaneously reject them from the batch.

All kinds of printing flaws, colour consistency, splatters, shades; Small inclusions in the carton; Accuracy of finishing like some remnants of die-cutting process or completeness of metal foils are reliably detected and can be used as exclusion criteria.

Comprehensive reports enables to define acceptable quality criteria and to avoid restricted faults.

VARIOmatic

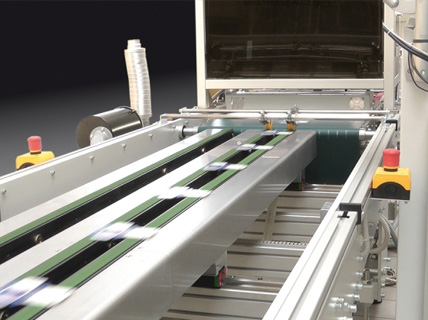

Such factors as modular construction, quick and simple setup and the long paths of operating area creates VARIOmatic very interesting solution designed for blank’s inspection and packages serialization by means of inkjet printing.

VARIOmatic is also interesting solution for other operations like inserting, tape dispensing or Braille UV printing, usable in digital printing sector as well.

SPECIFICATIONS :

vacuum assisted belt feeder with separate stepless speed drive

optional alignment module

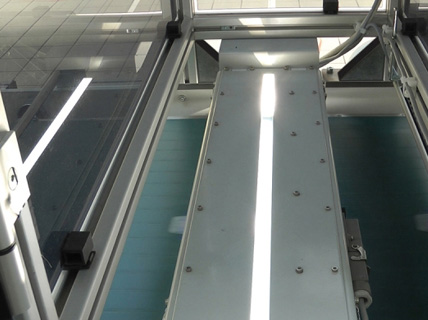

suction belt ( 500 mm wide ) section – 1st operating area

3 long tracks with suction belts – 2nd operating area

ejector module for removing failed blanks

delivery section ( shingle blanks type ) with non-stop control and separate stepless speed drive

optional stacking module